Composite Parts and Assembled Structures

Leading the Way in Marine Composite Parts and Structures

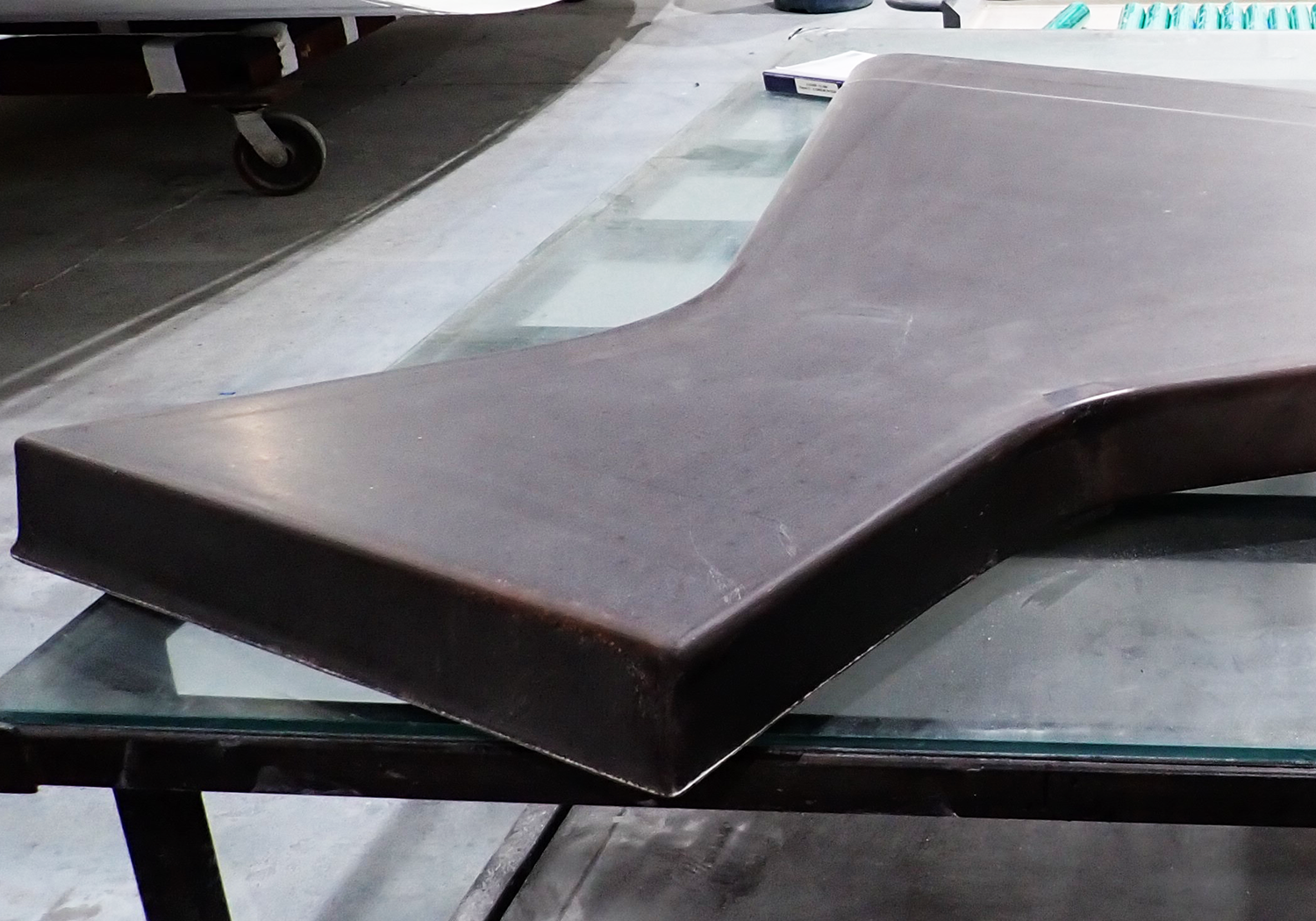

At Janicki, we specialize in producing high-performance composite parts and assembled structures that meet the most demanding industry standards. Our extensive experience in utilizing advanced composite materials allows us to fabricate large-scale, complex parts with exceptional precision and durability.

Key Features

Advanced Composite Fabrication Techniques

At Janicki Marine, we utilize a range of cutting-edge composite fabrication techniques to consistently deliver top-tier results for our clients:

- Wetlay Processes: Our wetlay techniques ensure that each composite material layer is meticulously laid down and properly bonded. This process provides reliability and durability in all applications.

- Prepreg Processes: We use pre-impregnated materials to offer superior control over resin content and fiber orientation, resulting in high-performance parts with consistent quality.

- Infused Processes: By utilizing infused processes, we achieve optimal resin distribution within the composite, enhancing the structural integrity and performance of the final product.

Expertise in Large-Scale, Complex Part Fabrication

Janicki is renowned for our ability to fabricate large-scale, complex composite parts. Whether it’s for aerospace, marine, or industrial applications, our team has the expertise to take on the most challenging projects. We pride ourselves on delivering parts that meet stringent specifications, ensuring they perform flawlessly in their intended applications.

Precision Machined Trimming and Bonded Subassemblies

We also offer precision machining services for all composite parts, guaranteeing a perfect fit and finish. Our state-of-the-art CNC machining capabilities enable us to achieve extremely tight tolerances and precise dimensions, allowing for seamless integration into larger assemblies.

In addition, we manufacture bonded subassemblies to provide a comprehensive solution for your composite needs. Our bonded subassemblies are meticulously engineered to deliver superior strength and performance, consistently meeting or exceeding industry standards.

Ready to Start Your Project?

Let Janicki bring your vision to life with our advanced composite solutions.

Success Stories

OPI selected Janicki due to their expertise in composites manufacturing as well as their capabilities and experience designing and building high-precision parts across a broad range of markets, including energy and marine. Janicki’s proprietary 5-axis CNC machines are state-of-the-art in scale and precision, and their team has broad experience specializing in large complex projects with demanding timelines in unique and innovative applications.

– Oscilla Power

I have been extremely impressed by the dedication and professionalism of the Janicki team. Their commitment to meeting deadlines and maintaining high-quality standards is evident in every interaction. The team’s timely communications and proactive approach ensured that our projects ran smoothly and efficiently, making our collaboration both pleasant and productive. I highly recommend Janicki for their exceptional service and expertise.

– Damon Smith, Director of Composites at Saildrone